Key takeaways you will find in this article

- •Facilities management KPIs are critical aspects of facilities management

- •While the benchmarks can vary by industry, they provide a good rule of thumb to create standard operating procedures

- •Facilities management software helps leaders track and report on KPIs

Table of contents

- What are facilities management KPIs?

- What are examples of facilities management KPIs?

- How can tracking facilities management KPIs reduce costs?

- How to choose the right KPIs for your facility

- What facilities management KPIs should I track?

- What facilities management KPIs should I track?

- Using facilities management software to track KPIs and other metrics

If you want your facility to perform at its best, you need to first define what success looks like for you. Once you’ve done that, you can build a roadmap to guide you. With the current emphasis on budgets, facilities teams are under growing pressure to do more with less. Tracking facilities management key performance indicators (KPIs) helps cut unnecessary spending, improve efficiency, and justify investments.

In this article, we’ll explore what facilities management KPIs are, which ones to track, how they support cost reduction, and why software makes a difference in tracking performance metrics.

What are facilities management KPIs?

Facilities management KPIs (key performance indicators) are measurable metrics. Applied to facilities, they help teams monitor performance, identify trends, and support data-driven decisions. They reflect how well your facilities, staff, equipment, and vendors perform. They also tell leaders where improvements can reduce costs.

By consistently measuring KPIs, facilities teams can make smarter, faster decisions. KPIs also help improve operational efficiency, reduce reactive maintenance, extend asset lifecycles, and allocate resources more effectively.

What are examples of facilities management KPIs?

Many KPIs are tailored to the specific needs of your facility, but here are several commonly used across industries:

- Work order completion time – Measures average time from request to completion

- Planned maintenance percentage (PMP) – Ratio of planned vs. reactive maintenance

- Asset downtime – Tracks time critical equipment is non-operational

- Maintenance cost per square foot – Helps identify facilities that are more expensive to maintain

- Energy usage – Monitors consumption trends to reduce utility costs

- Occupant satisfaction score – Measures user sentiment on facility conditions and services

- Response time to service requests – Indicates team responsiveness and workload balance

- Work orders per technician – Helps optimize labor distribution

These metrics clearly show your facility’s performance and give teams a baseline for cost-saving initiatives.

How can tracking facilities management KPIs reduce costs?

Tracking and analyzing KPIs helps your team work smarter, not harder. Here’s how:

Improve decision-making with data

Accurate performance data helps you make informed decisions about maintenance schedules, staffing, and vendor selection.

Control costs and boost efficiency

By identifying inefficiencies—like high overtime costs or frequent emergency repairs—you can adjust workflows and reduce waste.

Justify staffing and resource allocation

KPIs help make the case for additional hires or reallocation of tasks by showing exactly where bottlenecks occur.

Support long-term planning

Facilities KPIs provide valuable input for budgeting, capital planning, and lifecycle forecasting. That means fewer surprises and more proactive management.

How to choose the right KPIs for your facility

Not all KPIs are created equal. Focus on those that directly support your team’s strategic goals and operational needs.

Align KPIs with your team’s goals

If your team is focused on preventive maintenance, prioritize metrics like PMP or mean time between failures (MTBF).

Consider compliance and stakeholder expectations

Different stakeholders—whether finance teams, school boards, or regulatory bodies—may require specific reporting metrics.

Start small: choose a handful of high-impact KPIs to monitor, then refine your list as your data maturity grows.

What facilities management KPIs should I track?

There are unlimited possibilities for facilities leaders to track. We’ve narrowed it down to the most common and meaningful KPIs, listed below.

What facilities management KPIs should I track?

There are endless possibilities regarding what you can track within your facility. We’ve narrowed it down to the most common and meaningful KPIs, listed below.

1. User satisfaction

User satisfaction is typically measured through surveys or feedback forms using a rating scale or questionnaire to assess the satisfaction level of facility users.

Benchmark: High user satisfaction is often indicated by a score of 80% or above on the satisfaction scale.

2. Reactive maintenance vs. preventive maintenance

While preventive maintenance helps reduce unexpected breakdowns, reactive maintenance is sometimes unavoidable. Tracking the ratio between the two gives proactivity insight. A high reactive maintenance ratio can point to scheduling or resource allocation gaps.

Tracking the ratio between planned and reactive maintenance work can help you determine if you need to invest more time or funds in planned work.

Benchmark: A typical standard is 80% planned maintenance and 20% reactive maintenance. However, very few organizations can achieve that standard. We recommend aiming for a healthy mix of 60/40 planned vs. reactive.

3. Work order completion time

Work order completion time tracks the total time it takes for your team to complete a task. This KPI helps you spot inefficiencies and reveals if certain work orders cause delays.

Benchmark: Many organizations aim to resolve most work orders within 3–5 business days, depending on urgency. Emergency work orders should be completed within 24 hours.

4. Average work request response time

This KPI measures how quickly your team responds to a work request. It’s slightly different from completion time because it focuses on responsiveness, not resolution. Tracking this can highlight whether requests are sitting idle before action is taken.

Benchmark: Many organizations aim to respond to work orders within the same business day.

5. System/equipment/asset downtime

This KPI tracks the amount of time critical equipment or systems are unavailable due to breakdowns, repairs, or maintenance. Excessive downtime drives up costs and can impact operations.

Benchmark: Downtime standards vary by industry, but many facilities target less than 5% downtime for critical equipment.

6. Preventive maintenance compliance

Most folks in the facilities management sector know that preventive maintenance saves your bottom line in the long run. That’s why tracking how much preventive work your organization completes is essential.

To find the preventive maintenance compliance percentage, take the total number of preventive maintenance tasks completed on schedule, divide by the total number of preventive maintenance tasks, and multiply by 100.

Benchmark: Ideally, preventive maintenance compliance should be close to 100%, though this is extremely difficult. A benchmark standard could be set at a minimum of 90% compliance.

7. Average response time for work order resolution

One of the most common KPIs is the time to complete work orders. This shows how quickly your team responds to work orders.

The average response time can be found by taking the total time taken to resolve work orders, divided by the total number of work orders.

Benchmark: The standard for average response time varies depending on the facility and industry. However, a common target is to aim for a response time of less than 24 hours.

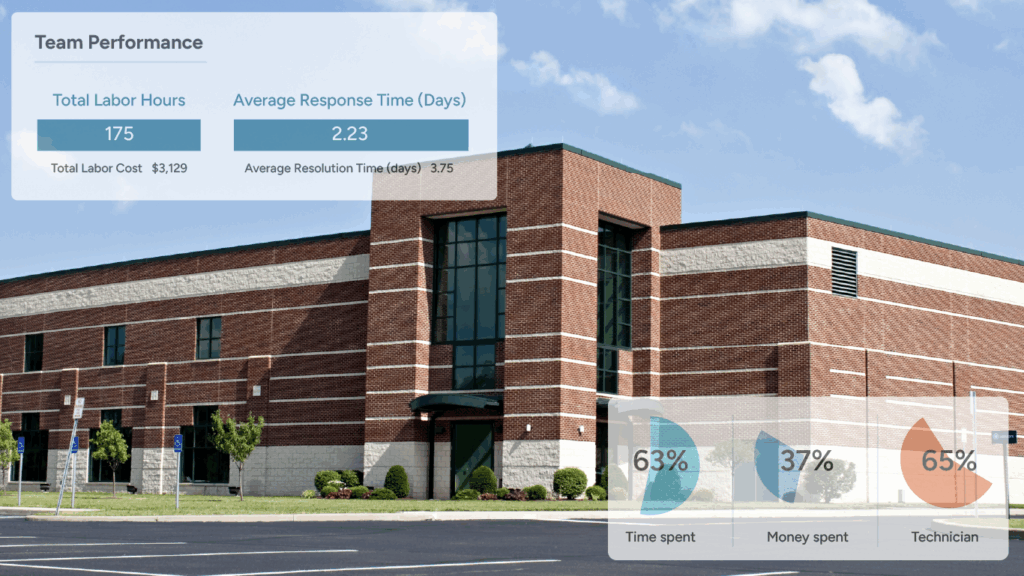

Capture, analyze, and discover actionable insights

Understand equipment repair trends, analyze labor cost and time, justify capital improvements, and plan your organization's budget expenditure.

8. Gross facilities management costs

This broad KPI can be intimidating, but use this information to compare it to the anticipated facility costs of similar institutions and see where you fall. Average facility management costs vary by industry, but finding comparable metrics can help you identify areas of success and improvement.

The gross facilities management costs can be calculated by adding up the total costs associated with managing and maintaining facilities, including labor, materials, equipment, and overhead expenses.

Benchmark: Ideal gross facilities management costs can vary significantly based on facility size, industry, and location. To find an accurate benchmark, look at similar facilities in your industry.

9. Operations cost per square foot

Determining operations costs can help you monitor workforce efficiency, asset usage, equipment performance, and more.

To calculate your operation costs per square foot, add up your total operations costs and divide the total by the square footage of your facility.

Benchmark: Standards for operations cost per square foot vary based on the facility type and industry. Compare the averages of similar facilities to determine an average.

10. Utility cost per square foot

By tracking the cost to keep your facility running (electricity, heating, cooling, etc.), you can identify any disproportionate costs and begin deciding where to economize or upgrade. After you track this KPI for several months, you can more easily spot anomalies in the data and enact change quickly.

To calculate the utility cost per square foot, add up your utility costs (e.g., electricity, water, gas) and divide the total by the total square footage of the facility

Benchmark: The standards for utility cost per square foot can vary depending on your facility’s location, size, and energy efficiency measures. An average utility cost per square foot can range anywhere from $1.00 to $2.50 or more.

11. Cleaning cost per square foot

If your facility’s cleaning costs rise quickly, it might indicate a problem with custodial processes or the equipment itself. On the other hand, a decrease in cleaning costs may be a sign of effective change, but an unexplained or significant dip might indicate an unwanted decline in necessary cleaning tasks.

Calculate your cleaning cost per square foot by adding the total cleaning expenses and dividing by the square footage of your facility.

Benchmark: The standards for cleaning cost per square foot can vary based on the facility type, level of cleanliness required, and industry, but can average anywhere between $0.10 and $0.25 on average.

12. Security cost per square foot

Monitoring security costs can help you pinpoint trends and identify potential weaknesses. Ultimately, this can drive important changes, whether that means increasing security measures or switching to a different security solution.

Calculate your average security cost per square foot by adding your total security costs and dividing them by the total square footage of your facility.

Benchmark: Standards security costs change depending on the level of security required, facility location, and industry. Generally, you can expect to pay about $1.00 per square foot or more.

13. Renovations, new construction, and major maintenance costs

Tracking each type of major maintenance spending can help you determine where to allocate funds. Depending on the time and cost, you can make more informed decisions when comparing the benefits of refurbishing or starting fresh with future projects.

Benchmark: Standard pricing for renovations, construction, and other major maintenance expenses depends on the size, complexity, location, and industry of the facility. For example, pricing can range anywhere from $30 per square foot to $300 or more.

14. Maintenance costs per square foot

This KPI measures the total maintenance costs relative to your facility’s size. It helps you benchmark performance across sites and identify facilities that may be more expensive to maintain.

Benchmark: This varies widely by industry and budget.

15. Space utilization

Space utilization measures how effectively your facility uses its available square footage. It ensures that space isn’t underutilized or overcrowded.

Benchmark: A healthy utilization rate is typically between 70–90%. Below that may indicate wasted space. Percentages over that indicate potential overcrowding.

16. Employee satisfaction surveys/scores

Employee satisfaction is often measured through surveys that capture workplace comfort, safety, and functionality. Facilities directly affect these scores through lighting, HVAC performance, layout, and cleanliness.

Benchmark: Many organizations aim for 80% or higher employee satisfaction.

17. Gross facilities management costs per square foot

This KPI captures the total cost of managing and maintaining your facility. This number should include maintenance, utilities, cleaning, security, and other overhead, divided by square footage. It provides a high-level picture of total operating expenses.

Benchmark: This varies widely by industry and budget.

18. Money spent on new equipment versus repairs

This KPI helps determine if replacing equipment or repairing it is more cost-effective. Tracking these costs prevents overspending on assets near the end of their lifecycle.

Benchmark: A common guideline is the 50% rule. If repair costs exceed 50% of replacement costs, replacement may be the better option.

19. Customer satisfaction rates

For facilities that serve external customers, customer satisfaction provides insights into how well facilities meet user needs.

Benchmark: Many organizations aim for 85% or higher customer satisfaction.

* Please note that the benchmarks provided are general guidelines distilled from many facilities management resources and may vary depending on the specific context, industry, and requirements.

Using facilities management software to track KPIs and other metrics

Tracking and managing key performance indicators can be overwhelming. There are countless assets and metrics to manage and even more data to store as the years go by. To keep things organized, consider a facilities management software solution.

FMX can help you manage and track your facility’s performance and provide a detailed report summarizing your data and enabling actionable insights. Whether you’re looking closely at asset maintenance KPIs or searching for equipment maintenance insights, we can help.

Learn more about our facilities reporting and analytics software to discover what we can help you track for your facility.

Written by

Dana Grove

Manager, Brand and Content at FMX